Contact Person: Miss Norejet

Mobile Phone:+8613690188010

WhatsApp:+8613690188010

E-mail: market@norejet.com

skype:christin-tz13

Add:Panyu Area Guangzhou China

Which is more common in the daily necessities industry, inkjet printers or laser printers?

When discussing the question of which is more commonly used in the production of daily necessities, inkjet printers or laser machines, we need to conduct in-depth analysis from multiple dimensions, including working principles, usage scenarios, cost-effectiveness, technical characteristics, market demand, etc. Both devices play an important role in modern industrial production, but there are certain differences in their application scope and popularity.

1、Working principle and application scenarios

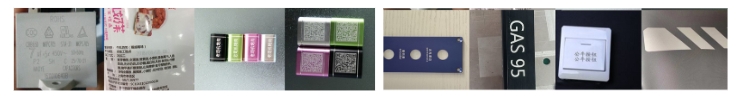

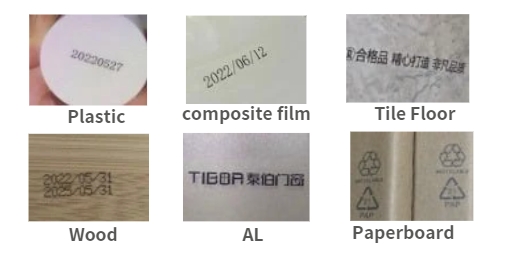

First of all, from the working principle point of view, the inkjet printer mainly leaves ink marks on the surface of objects through inkjet printing, which is visually intuitive and easy to identify. The inkjet printer is suitable for surfaces of various materials, including paper, plastic, glass, etc., so it is widely used in packaging identification, production date printing, batch number marking, etc. The laser machine uses laser to irradiate the surface of the object and mark it through the photothermal effect. The marking content can be text, numbers, patterns, etc., and the marking effect is long-lasting and not easy to wear. The laser machine has advantages in precision and depth control, and is especially suitable for occasions that require high-precision marking, such as electronic components, medical packaging, high-end daily necessities, etc.

In the production of daily necessities, inkjet printers are more common in the early stages or in companies with smaller production scales because of their relatively low cost, easy operation, and ability to meet most basic marking needs. However, with the continuous improvement of product quality and the intensification of market competition, more and more daily necessities manufacturers are beginning to pursue higher quality marking effects, and the advantages of laser machines are highlighted at this time. Especially in the field of high-end daily necessities, such as luxury goods packaging, precision instrument housings, etc., laser marking has become the preferred marking method with its unique texture, precise size and long-lasting preservation.

2、 Technical characteristics and market demand

In terms of technical characteristics, laser machines perform well on automated production lines with their high precision, high speed and high efficiency. With the development of intelligent manufacturing and industrial Internet, the application scope of laser machines in the production of daily necessities continues to expand, from simple text marking to complex pattern engraving, they can easily cope with it. At the same time, laser marking also has the advantages of environmental protection and pollution-free, which meets the requirements of modern enterprises for green production.

In terms of market demand, with the improvement of consumers' requirements for product quality and the increase in personalized needs, laser marking is favored for its unique visual effects and customization capabilities. More and more daily necessities manufacturers are beginning to use laser machines for product identification and brand promotion to enhance product added value and market competitiveness.

Summary

To sum up, although both inkjet printers and laser printers are widely used in the production of daily necessities, which one is used more depends on the actual situation of the enterprise and market demand. For enterprises with limited budgets and small production scales, inkjet printers may be a more economical and practical choice; while for enterprises pursuing high quality, high efficiency, and green environmental protection, laser printers have more advantages. With the continuous advancement of technology and changes in market demand, the application of laser machines in the production of daily necessities will be more extensive and in-depth in the future.