Contact Person: Miss Norejet

Mobile Phone:+8613690188010

WhatsApp:+8613690188010

E-mail: market@norejet.com

skype:christin-tz13

Add:Panyu Area Guangzhou China

What are the components of a laser marking machine?

As an indispensable precision processing equipment in modern industry, the complex and delicate structure of the laser marking machine is the key to achieving efficient and accurate marking. Below, we will discuss in detail the main components and functions of the laser marking machine.

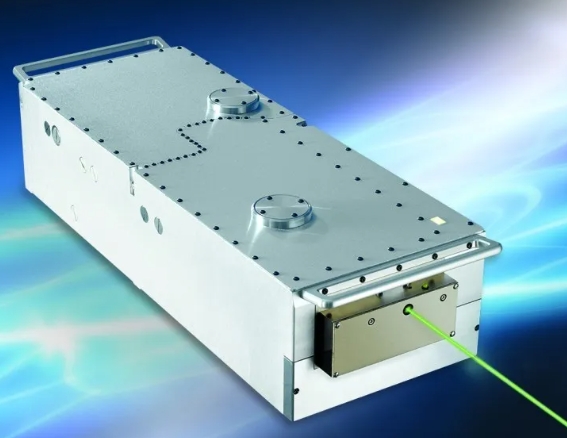

1. Laser

The laser is the core component of the laser marking machine, responsible for generating a high-energy laser beam. It is mainly composed of three parts: a pump source, a resonant cavity, and an output beam. The pump source injects energy into the resonant cavity through electricity or light energy, and excites the medium in the resonant cavity to produce lasers. Depending on the type of laser marking machine, the laser is also different. Common ones include CO2 lasers, fiber lasers, and semiconductor lasers.

CO2 laser: uses carbon dioxide as the main working medium and generates lasers through electrical excitation or optical pumping. The output laser wavelength is 10.6μm, which belongs to the infrared light category, and is particularly suitable for marking non-metallic materials such as wood, leather, paper, etc. Fiber laser: Uses optical fiber as a gain medium, and generates lasers in the optical fiber through pump light. Fiber lasers have the advantages of good beam quality, high efficiency and long life, and are widely used in marking of metals, plastics and other materials. Semiconductor laser: Using semiconductor materials as gain media, laser is generated by electron-hole recombination. Semiconductor lasers are small in size, light in weight and high in efficiency, suitable for integrated and portable applications.

2 . scanning system

The galvanometer scanning system is the key part of the laser marking machine to control the movement and positioning of the laser beam. It consists of two parts: an optical scanner and a servo control. The optical scanner usually includes two mirrors (X mirror and Y mirror), which control the movement of the laser beam in the horizontal and vertical directions respectively. The servo control system is responsible for receiving signals from the computer control system and accurately controlling the rotation angle and speed of the mirror by driving the motor, thereby achieving precise positioning of the laser beam.

The galvanometer scanning system uses new technologies, new materials and new processes to ensure that the laser beam can maintain stable focus and precise path control during high-speed movement. This system not only improves the marking efficiency, but also achieves accurate marking of complex graphics.

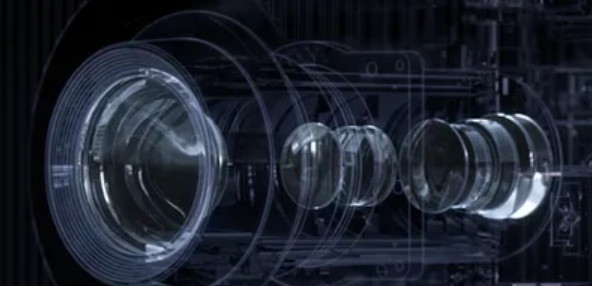

3 . Focusing system

The focusing system is a device in the laser marking machine that focuses the laser beam into a tiny spot. It usually consists of a focusing lens and an adjustment mechanism. The focusing lens is responsible for converging the laser beam into an extremely fine spot, while the adjustment mechanism is used to adjust the position and angle of the focusing lens to ensure that the spot size and shape meet the marking requirements.

The foc object point by point to form a clear mark. Since the size of the laser after focusing is eused laser beam is like a fine "tool" that can remove the material on the surface of thextremely small and the heat-affected area is small, fine processing can be achieved to avoid unnecessary damage to the material.

4 . Computer control system

The computer control system is the "brain" of the laser marking machine and is responsible for the control and management of the entire marking process. It is mainly composed of a computer, a control card and control software. The user inputs the graphics or text information to be marked through the computer, and the control software converts this information into control signals and sends them to the control card. The control card drives the laser, galvanometer scanning system, focusing system and other components to work together according to the signal to complete the marking task.

The computer control system has powerful editing and processing capabilities, supports a variety of graphics and text formats, and can achieve accurate marking of complex graphics. At the same time, it also has a friendly user interface and rich functional options, which is convenient for users to operate and set.

5 . Equipment power supply system

The equipment power supply system is a device that provides power for various laser system components such as lasers and control systems. It is usually composed of power modules, voltage stabilization circuits and protection circuits. The power module is responsible for converting the external power supply into voltage and current suitable for the operation of each component; the voltage stabilization circuit ensures the stability of the output voltage and current; the protection circuit is used to monitor the power supply status to prevent abnormal conditions such as overvoltage and overcurrent from damaging the equipment.

The stability and reliability of the equipment power supply system are crucial to the normal operation of the laser marking machine. It can not only ensure the stability of the equipment during long-term work, but also cut off the power supply in time under abnormal conditions to protect the equipment from damage.

6 . Summary

As an important equipment in modern industry, the laser marking machine has a complex and delicate structure. The main components such as lasers, galvanometer scanning systems, focusing systems, computer control systems and equipment power supply systems work together to achieve efficient and accurate marking tasks. With the continuous advancement and innovation of technology, laser marking machines will play an important role in more fields and bring more convenient and efficient solutions to industrial production.